T

S

K

I

n

d

u

s

t

r

i

a

l

S

e

r

v

i

c

e

s

- We Are Leading Provider Of Industrial Solutions.

- +91 8838805499

- Zuzuvadi Sipcot -1,Hosur - 635126

CNC Turning

CNC Turning is commonly used for cylindrical shaped workpieces, however, it can be used for square or hexagonal-shaped raw materials. The workpiece is held in place by a 'chuck'. The' chuck' spins at varying RPMs (rotations per minute). Unlike a traditional lathe, today's machines are numerically controlled.

CNC turning is a machining process that uses computer-controlled lathes to rotate a workpiece and cut material with precision CNC turning tools. It is commonly used in industries such as aerospace, automotive, medical, and electronics for CNC turning producing cylindrical components, shafts, and fittings.

CNC turning works by securing a workpiece in a chuck or collet and feeding cutting tools along the rotating axis to shape the material. Its key features include CNC turning high accuracy, repeatability, versatility in machining various materials like metals, plastics, and composites, and the ability to produce complex geometries.

CNC turning offers several advantages including CNC turning automation, faster production rates, reduced labor costs, and enhanced consistency in part quality. It enables CNC turning intricate designs, tight tolerances, and efficient material utilization, making it ideal for high-volume manufacturing.

Yes, CNC turning is suitable for prototyping and small batch production due to its flexibility in programming CNC turning tool paths and setups. It allows for rapid CNC turning iteration of designs, quick setup changes, and cost-effective production of custom parts without the need for specialized tooling.

CNC turning contributes to precision engineering by achieving exact dimensions, surface finishes, and geometric tolerances with minimal CNC turning operator intervention. It supports CNC turning innovative design solutions, improves part performance, and enhances product reliability in diverse industrial applications.

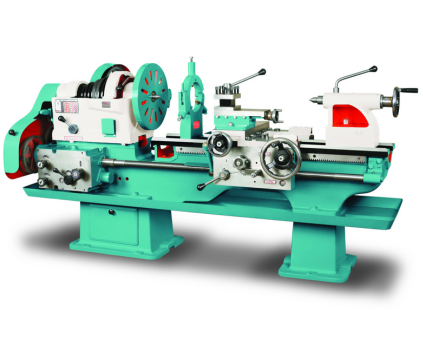

A lathe is a machine tool that rotates a workpiece on its axis, enabling various machining operations such as cutting, drilling, facing, and turning to be performed.Lathes are essential in industries like aerospace, automotive, metalworking, and woodworking for shaping lathe cylindrical components and creating precise geometries.

A lathe works by holding a workpiece securely in a chuck or collet and feeding cutting tools against it to remove material and shape the part. Its key features include lathe high precision, versatility in machining materials like metals, plastics, and wood, and the ability to produce intricate lathe profiles and threads.

Common types of lathes include engine lathes, CNC lathes, turret lathes, and automatic lathes. Each type of lathe is designed for specific lathe machining tasks and production requirements, offering varying levels of automation, speed, and capabilities.

Lathes offer several advantages including lathe versatility, efficiency in producing cylindrical and symmetrical parts, and the ability to achieve high surface finishes and tight tolerances. They are well-suited for rapid prototyping, small batch production, and large-scale manufacturing applications involving lathes.

Yes, lathes are versatile machines used in both metalworking and woodworking industries. They are capable of lathe turning metal rods, shafts, and components as well as lathe shaping wood blanks, spindles, and decorative items, demonstrating lathe adaptability across different materials and industries.

Drilling

Drilling