T

S

K

I

n

d

u

s

t

r

i

a

l

S

e

r

v

i

c

e

s

- We Are Leading Provider Of Industrial Solutions.

- +91 8838805499

- Zuzuvadi Sipcot -1,Hosur - 635126

Press Components

Press components, which include molds with a thickness of 0.5 to 8 mm, dies, and punches, are crucial equipment in the manufacturing process. These elements are essential for precisely and consistently forming raw materials into completed goods. They are widely used in a variety of industries, including electronics, automotive like Handle Bar, side stand and cover stand and they make it easier to produce goods in large quantities, including plastic components and metal sheets. Press components with bespoke designs ensure efficiency and quality in production lines across the globe by providing variety in manufacturing processes.these components allow the fabrication of a wide range of products that fulfill demanding criteria.

Sheet Metal Parts are components manufactured from thin metal sheets, such as steel, aluminum, or copper. They are widely used in industries like automotive, aerospace, electronics, and construction for fabricating Sheet Metal Parts enclosures, brackets, panels, and structural components.

Sheet Metal Parts are typically manufactured through processes like cutting, bending, forming, and welding. CNC (Computer Numerical Control) machines are often used for precise cutting and shaping Sheet Metal Parts, ensuring high accuracy and repeatability in production.

Sheet Metal Parts offer several advantages including strength, durability, lightweight properties, and the ability to achieve complex shapes. Sheet metal parts are cost-effective for mass production and provide excellent mechanical properties suitable for various applications.

Yes, Sheet Metal Parts can be customized in terms of size, shape, thickness, and finish to meet specific design and functional requirements. This customization flexibility allows for tailored solutions in industries requiring unique designs or intricate geometries. Sheet Metal Parts are adaptable to diverse manufacturing needs, ensuring precise fit and functionality in various applications.

Sheet Metal Parts contribute to sustainable manufacturing practices by optimizing material usage, minimizing waste, and facilitating recyclability. They support green initiatives by reducing environmental impact throughout their lifecycle. Sheet Metal Parts play a crucial role in eco-friendly production methods, promoting resource efficiency and responsible material management.

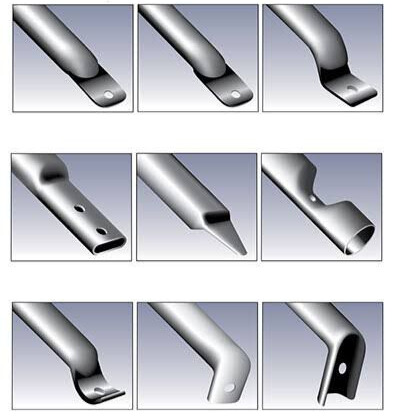

Tubular parts are components made from hollow cylindrical shapes, often manufactured from materials like steel, aluminum, or stainless steel. They find extensive applications in industries such as automotive, aerospace, furniture, and construction for fabricating tubular parts structures, frameworks, and support systems.

Tubular parts are typically manufactured through processes like tube bending, welding, cutting, and machining. CNC (Computer Numerical Control) machines are frequently used for precision tube bending and shaping tubular parts, ensuring high accuracy and consistency in production.

Tubular parts offer several advantages including lightweight properties, cost-effectiveness in material usage, and the ability to withstand torsional and compressive loads. They are versatile for creating complex geometries and structures, making them ideal for applications requiring tubular parts efficient design and functionality.

Yes, tubular parts can be customized in terms of diameter, length, thickness, and finishing to meet specific design and functional requirements. This customization flexibility allows for tailored solutions in industries requiring unique tubular parts designs or specialized applications.

Tubular parts contribute to efficient manufacturing processes by optimizing material usage, reducing assembly time, and enhancing product durability. They offer cost-effective solutions for producing lightweight and structurally sound components, supporting tubular parts streamlined production and logistics operations.